The Production Refine Behind Switch Over Backlighting: What You Need to Know

The production process behind button backlighting involves intricate actions that secure capability and longevity. From the option of materials to the assembly of elements, each stage is crucial. Automated equipment plays a considerable duty in incorporating LEDs and diffusive aspects. Quality control procedures further guarantee that the last item fulfills requirements. As modification alternatives increase, the potential for ingenious layouts emerges. What elements will shape the future of button backlighting technology?

Comprehending Change Backlighting Innovation

Although switch backlighting might appear like an easy attribute, it incorporates numerous innovations that improve customer experience in electronic gadgets. At its core, backlighting offers to illuminate buttons, making them noticeable in low-light settings. This capability relies upon various techniques, such as LED and fiber optic innovations, each offering distinct benefits. LEDs are widely preferred for their effectiveness, long life, and lively colors, permitting customizable lights alternatives. On the other hand, fiber optics can produce a softer glow, providing an extra cosmetically pleasing appearance.Moreover, the assimilation of backlighting can improve user ease of access, specifically for individuals with visual disabilities. The style of backlit buttons also takes into consideration energy intake, as modern tools intend to balance illumination with battery life. Eventually, the application of button backlighting technology plays a vital function in enhancing the use and appeal of electronic gadgets, transforming ordinary interfaces right into aesthetically involving experiences.

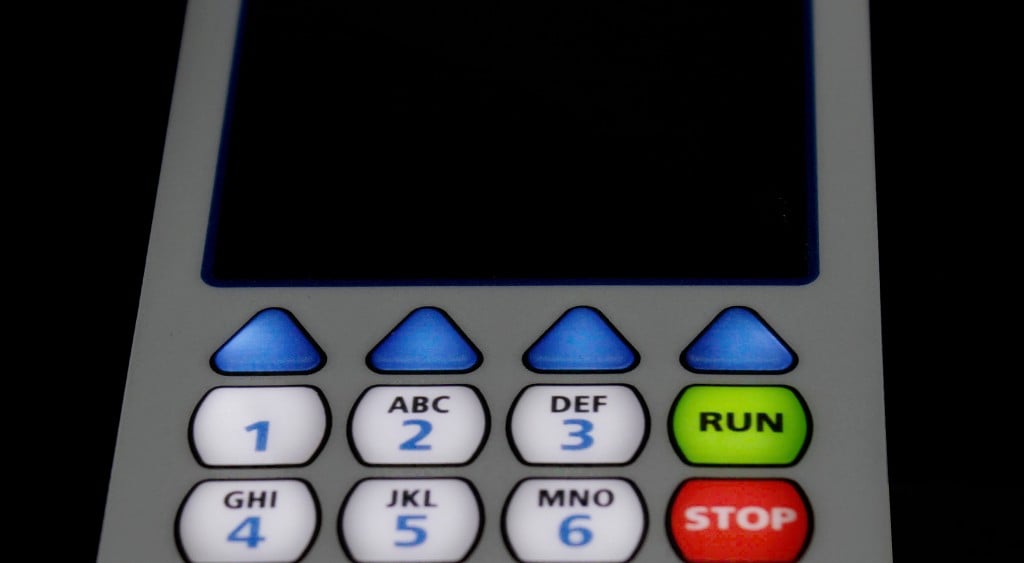

Trick Elements of Backlit Changes

The important elements of backlit switches comprise several crucial elements that collaborate to supply effective lighting and functionality. At the core is the button system itself, which can be either digital or mechanical, enabling for customer communication. Bordering this device are LED lights, which supply the illumination needed for exposure in low-light conditions. These LEDs are typically placed on a circuit card, assuring appropriate connectivity and power distribution.Additionally, a diffuser is typically utilized to uniformly disperse the light released by the LEDs, producing an uniform glow across the switch surface area. The real estate of the button plays a considerable role as well, as it should safeguard interior elements while allowing light to travel through purposefully placed openings or transparent materials. A printed graphic overlay might be applied to convey signs or message, enhancing functionality and aesthetics. Together, these parts ensure the performance of backlit switches in numerous applications.

Material Option for Longevity and Looks

Product selection plays an essential role in balancing durability and aesthetic appeals in switch backlighting. Secret buildings of materials, such as resistance to wear and ecological factors, greatly affect their durable efficiency. Furthermore, aesthetic design factors to consider have to align with performance to develop visually appealing and durable products.

Trick Product Characteristic

Resilience and appearances are crucial consider the material choice procedure for button backlighting. The materials used have to stand up to mechanical anxiety, heats, and possible chemical direct exposure while maintaining their aesthetic allure. Usual choices consist of polycarbonate and acrylic, which provide robust effect resistance and optical clarity. These products can sustain repeated use without fracturing or fading. Furthermore, the option of light diffusion residential or commercial properties is essential; materials should successfully disperse light uniformly to enhance exposure. Surface area therapies, such as coverings, can additionally improve longevity and scratch resistance. Eventually, selecting the appropriate materials assurances that switch backlighting does accurately with time, while also adding to the general design and customer experience.

Visual Layout Factors To Consider

Durable Efficiency Factors

The interaction in between aesthetics and capability extends past visual appeal, including the durable performance of switch backlighting. Material option is necessary in achieving resilience and preserving aesthetic top qualities with time. Premium plastics, such as polycarbonate or abdominal muscle, are typically preferred for their resistance to use and ecological elements. In addition, the choice of LED elements influences longevity, as superior-grade LEDs offer improved brightness and lowered warmth outcome. Coatings, such as uv-resistant or anti-fingerprint surfaces, can even more protect versus deterioration and discoloration. By incorporating durable products and progressed technologies, suppliers can ensure that button backlighting not just meets aesthetic requirements but likewise withstands the roughness of daily use, eventually boosting customer fulfillment and product lifespan.

The Assembly Process of Backlit Changes

The assembly process of backlit switches includes meticulous element preparation methods to establish compatibility and performance. A structured setting up line workflow is necessary to maximize efficiency and lessen production time. Additionally, durable top quality control actions are applied to assure that each button fulfills industry standards and customer assumptions.

Part Prep Work Methods

Efficient setting up of backlit buttons begins with precise preparation of their parts, making sure that each component meets the required requirements for functionality and durability. This prep work procedure includes the selection of high-grade products, such as long lasting plastics and effective light-emitting diodes (LEDs) Each component undertakes extensive evaluation and testing to recognize any kind of issues that could harm performance. In addition, elements might be coated or pre-treated to enhance their resilience versus wear and tear. Switch Backlighting. Proper cleansing and taking care of strategies are additionally critical to stop contamination prior to setting up. By implementing these component prep work strategies, suppliers can simplify the setting up process, decrease the likelihood of failures, and enhance the overall high quality of the last backlit switch product

Assembly Line Process

Streamlining the production line operations for backlit switches involves a collection of coordinated actions that assure each part is properly integrated into the end product. The base of the switch is placed on the conveyor system, where automated machinery properly places the LED lights into the assigned ports. Following this, a layer of diffusive product is added to guarantee also light distribution. Next off, the button cap is safely affixed, and electric connections are made with precision to assure functionality. Workers keep an eye on the procedure at various stages, looking for positioning and safe installations. you could try here Finally, the put together buttons relocate to product packaging, prepared for delivery. Each action is made to enhance effectiveness while keeping the honesty of the end product.

Quality Control Procedures

Quality control measures in the setting up process of backlit buttons are important to confirm that each device fulfills strict efficiency and visual standards. At numerous stages of setting up, visual inspections are performed to determine any kind of defects in components, such as inappropriate LED positioning or damaged soldering. Practical testing is carried out to verify that the backlighting runs correctly, with uniform brightness and shade uniformity throughout each button. Additionally, automated testing equipment may be utilized to inspect for electric integrity and responsiveness. Any kind of units falling short these assessments are revamped or discarded to preserve quality control. Detailed documentation of these quality checks likewise promotes traceability and constant renovation, validating that manufacturing methods advance to meet consumer assumptions and market requirements.

Top Quality Control Steps in Production

While assuring the integrity of switch backlighting manufacturing, manufacturers execute a range of quality assurance measures to preserve high criteria. These measures encompass several stages, beginning with the choice of raw materials. Suppliers are carefully vetted to assure that just premium parts are made use of. During the manufacturing process, routine assessments are performed to identify any type of defects or inconsistencies in the backlighting systems.Automated testing devices plays an essential function in examining the performance and longevity of the items. This consists of look for luminescent strength, color accuracy, and lifespan. Additionally, manufacturers typically utilize analytical procedure control (copyright) methods to monitor manufacturing variables, enabling prompt modifications when discrepancies take place. Post-production, final examinations ensure that the ended up products fulfill predefined requirements before they are packaged and delivered. By adhering to these complete high quality control steps, manufacturers can with confidence supply trusted and high-performing button backlighting services to their consumers.

Modification Options for Improved Individual Experience

A wide array of personalization options is readily available for switch backlighting, permitting users to boost their general experience. Users can pick from different colors, brightness degrees, and lighting impacts to tailor the backlighting to their preferences. Several makers give software program that enables users to produce dynamic illumination accounts, which can alter based upon use scenarios, such as pc gaming or inputting. Some switches also provide programmable attributes, allowing certain tricks to illuminate in distinct colors, helping in capability and aesthetics.Furthermore, users may select between various sorts of materials and surfaces for the button housing, influencing both the feel and look of the backlighting. Translucent or clear materials can enhance light diffusion, creating an extra uniform glow. Inevitably, these customization choices cultivate a personalized interface that not just improves use however additionally reflects individual design, adding to a much more appealing user experience.

The Future of Switch Backlighting Technologies

As innovation continues to advance, the future of button backlighting advancements is poised to deliver also much more advanced click to read more features and enhanced individual experiences. Emerging trends indicate a change towards adaptive lighting systems that adjust brightness and color based on user preferences and ambient conditions. This personalization could improve usability and availability, specifically for those with visual impairments.Furthermore, integration with smart home communities provides the potential for synchronized illumination impacts that improve the general environment of an area. Advancements in materials, such as flexible OLEDs, may cause thinner, a lot more effective designs, allowing for better convenience in applications.Additionally, energy-efficient remedies, such as solar-powered choices and low-power leds, will add to a lasting future in backlighting - Switch Backlighting. Advancements in manufacturing methods, such as 3D printing, might further assist in modification, enabling users to produce distinct button styles. In general, the future of switch backlighting promises a blend of performance, aesthetic appeal, and sustainability

Regularly Asked Inquiries

What Kinds of Applications Commonly Make Use Of Backlit Buttons?

Backlit switches are commonly made use of in various applications, including automotive dashboards, consumer electronic devices, webpage medical gadgets, and commercial control panels. These applications take advantage of improved visibility and usability, specifically in low-light problems, boosting customer experience and functionality.

How Do Backlit Switches Impact Energy Consumption?

Backlit switches can influence energy consumption by requiring extra power for lighting. Depending on the innovation made use of, such as LED versus typical bulbs, the effect on overall energy usage can differ substantially throughout various applications.

Can Backlit Switches Over Be Repaired if Harmed?

Backlit buttons, if harmed, can usually be repaired depending upon the degree of the damages. Small concerns like LED failing might be fixable, while much more extreme damage might require full replacement of the switch.

What Are the Safety Specifications for Backlit Change Production?

The safety and security criteria for backlit switch manufacturing include electric safety and security, product longevity, and customer ease of access. Conformity with policies warranties that products are trustworthy, lower threats, and provide a risk-free individual experience in different applications.

Exactly How Do Ecological Elements Impact Backlit Change Performance?

Environmental elements, such as temperature and moisture, considerably influence backlit switch efficiency. Severe problems can impact materials' resilience and light output, possibly causing decreased capability and life expectancy of the buttons under varying operational settings. Button backlighting may seem like a simple function, it incorporates various innovations that boost user experience in electronic tools. Material selection plays a vital function in stabilizing resilience and visual appeals in button backlighting. Resilience and appearances are vital variables in the product choice procedure for switch backlighting (Switch Backlighting). Visual layout plays a necessary role in the selection of products for button backlighting, as it directly affects customer understanding and satisfaction. Some buttons even supply programmable attributes, allowing particular tricks to illuminate in distinct colors, assisting in functionality and aesthetics.Furthermore, individuals may pick between various types of materials and surfaces for the button real estate, influencing both the look and feel of the backlighting